Canvas Signs Long-Term Enterprise Leases: Daley’s Drywall & Taping, Inc. and Nevell Group Inc. make long-term commitments to automation

Construction Dive

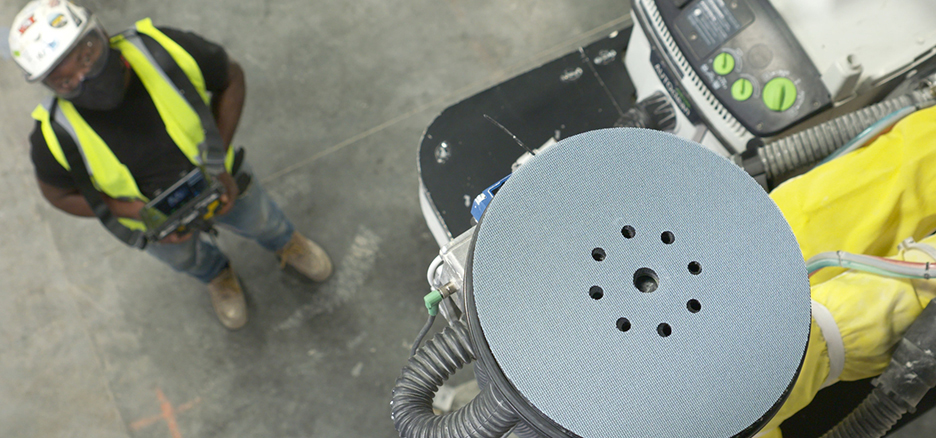

In response to widespread demand for its worker-operated drywall finishing machines, construction robotics company Canvas today announced that Daley’s Drywall & Taping, Inc., and Nevell Group Inc. (NGi) have both signed multi-machine, multi-year leases to strategically ensure they have priority access, giving them an edge over their competitors. Daley’s and NGi, two of the most innovative wall and ceiling contractors in the region, will independently operate Canvas’s ground-breaking robots on their job sites.

”We very clearly see the writing on the wall for the future of the drywall finishing industry,” said Daley’s Drywall & Taping VP Jonathan Hughes,“ and it tells us that we need to embrace automation sooner than later, as in right now.”

Hughes is referencing recent news articles that point to a series of bleak announcements for the construction trade, including:

- Shortage of workers: The shortage of skilled labor, now critical, is going to worsen. The Associated General Contractors (AGC) recently reported that 89% of contractors said they couldn’t find enough skilled workers to complete their projects..

- Rising wages: The “great resignation,” or the number of people leaving their jobs, also impacted the construction industry. Last month, the AGC reported that rising hourly wages attracted more workers to construction, but the industry still posted a record number of job openings.

- Lower productivity: The combination of fewer workers and rising wages not only makes construction more expensive, it also impacts productivity. In a not-uncommon scenario playing out across the country, workers are getting paid more while their productivity remains stagnant (or worse, declines).

Daley’s will be utilizing its Canvas machines on projects that have both Level 5 and Level 4 finishes. “We have used the machine on multiple projects, focusing on its safety and quality benefits,” Hughes says. “Now, with the machine capable of doing both Level 4 and Level 5, it opens up more opportunities for us to increase utilization.” Canvas recently announced its machine’s ability to do Level 4 Targeted Spray (in which only seams are sprayed instead of the entire wall), as well as super-high-quality Level 5 finishes. Canvas’s machine also consistently delivers projects in 40% less time than those that use traditional drywall-finishing processes.

Nevell Group Inc. (NGi), also a California-based drywall contractor, recently completed the drywall scope on the $174 million Sunnyvale Civic Center Modernization Phase I project for Hensel Phelps Construction using a Canvas machine with a Canvas-trained Nevell employee.

“The quality of finish that this machine produces is outstanding,” said Hensel Phelps Project Manager Andrew Cameron.“

We had piloted with the Canvas team at the San Francisco International Airport Harvey Milk Terminal 1 project several years ago when they were still a subcontractor, and we were blown away by both the simplicity of the process and the quality of the finish. The machine elevates the level of consistency, while also making the process more predictable.”

“Our clients, the most innovative general contractors in California, are continually seeking ways to improve project efficiencies,” said NGi CEO Chris Taylor. “As an early adopter of the Canvas robotic drywall finishing machine, NGi has worked closely with Canvas in the past year on increasing the machine’s capabilities. The machine’s new Level 4 Targeted Spray capabilities, which we helped to develop, will increase our ROI by improving schedules and reducing costs.

“There are any number of issues facing contractors these days,” Taylor concluded, “including diminishing ROI on jobs due to increased labor and material costs, as well as supply chain issues. In this environment, NGi is going to look at every possible opportunity to improve project efficiencies and outcomes. The Canvas machines enable us to take on more work without compromising safety and quality, and while also helping us retain and attract new skilled workers to the trade.”

“The current construction environment makes leasing the Canvas machines a strategic move, as owners will increasingly be looking to their contractors to reign in costs and boost productivity,” said Canvas’s new Chief Revenue Officer Chris Peterson. “The surest way to do that is by embracing automation as predictability in labor costs, availability, and quality are a concern.” Peterson added that as enterprise lease signers, both Daley’s and NGi will be first in line to receive additional machines as they are produced. “It’s a decision that will pay off quickly,” he said, “as news about the construction industry’s labor, cost and productivity outlook continues to paint a pretty dark picture. Technology and innovation, as Daley’s and NGi know, can help immensely.”

###